News Releases

Rokmaster Reports Updated Metallurgical Test Results For The Revel Ridge Project, BC

-Improved Main Zone Concentrate Gold Grade–

(Vancouver, September 30, 2020) – Rokmaster Resources Corp. (“Rokmaster” or the “Company”) is pleased to announce the results of recently completed bench scale metallurgical testing on its Revel Ridge polymetallic gold-silver project in British Columbia, Canada (“Revel Ridge” or the “Project”).

On February 25, 2020, the Company filed a Technical Report entitled “Updated Technical Report on the Revel Ridge Property (formerly J&L Property), Revelstoke Mining Division, British Columbia, Canada” (the “Technical Report”) which included the updated 2020 mineral resource estimate and a summary of the comprehensive metallurgical testing that had been completed up to the spring of 2014. Rokmaster’s team identified opportunities for project optimization in two areas: an increased mineral resource estimate, and improved mineral recoveries.

Additional metallurgical testing has been underway since July 2020. The new results from this testing indicate:

- Overall initial recovery of gold to gravity, zinc cleaner tail and lead concentrates is 74.3%, with the grade in the combined gravity products and zinc cleaner tails (the “combined gold concentrate”) at 33.2 g/t Au and 52.0 g/t Ag.

- The mineralization responds to gravity with the gold recoveries increasing with continuous gravity concentration and increased mass pull.

- Pyrite, which appears to carry minimal gold grade and interferes with zinc flotation and arsenopyrite-gold concentration, does not largely report to gravity circuit and can be separated after lead and prior to zinc flotation.

- Repeatability in flowsheet response, with the zinc cleaner tails carrying minimal zinc but increased gold grades.

- Grind sizes from the 2014 test work have been used in the 2020 test work to-date to achieve good grades and recoveries, namely a primary grind P80 of approximately 30µm and regrind P80 of approximately 10-15 µm.

- Carbon assays in the 2020 combined gold concentrate are relatively low at ~0.35% C.

Metallurgy

The Technical Report included the 2014 Test Work Program and identified metallurgical responses with gold, silver, lead and zinc recovery techniques that would include conventional crushing, dense media separation, grinding and flotation. The 2014 recovery of lead and zinc in concentrates, silver following the lead, followed by flotation of the zinc rougher tails produced a gold concentrate for potential pressure oxidation pre-treatment (“POX”). That followed by leaching and gold recovery from loaded carbon to produce gold doré from the Main Zone mineralization. Previous life of mine (“LOM”) production schedule average head grades reported were approximately 6.4g/t Au, 69.8g/t Ag, 2.2% Pb and 3.6% Zn; which aligns well with the Main Zone master composite bulk sample on which the current metallurgy was undertaken at: 6.4-7.7g/t Au, 57.2-66g/t Ag, 2.3% Pb and 3.7-4.1% Zn.

The objective of the current 2020 metallurgical program is to assess maximizing the gold recoveries to concentrates, while decreasing the mass pull to the gold concentrate. The intent was to potentially produce a gold concentrate for sale, and or reduce the mass of the concentrate and consequently the volume of concentrates shipped for sale or processed at a downstream hydrometallurgical plant. Minimal effort was made to optimize the lead and zinc recoveries; however, the grades were maintained in these batch tests, as the previous metallurgical test work had successfully obtained recoveries in locked-cycle tests and these have been reported.

The ongoing test program being undertaken at Base Metallurgical Laboratories Ltd. in Kamloops, BC, has included fourteen (14) flowsheet development tests on the Main Zone deposit master composite designated “JL-1” and comprised from seven (7) metallurgical variability composites (“VC’s”) that represent areas of the underground mine, taken from sample locations that intersect the different rock types and mineralization zones identified to-date.

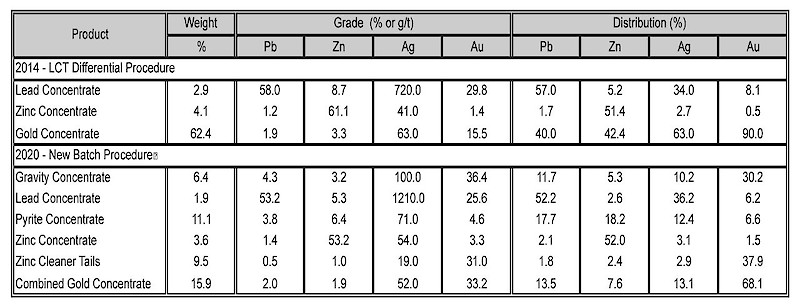

In 2014, the locked-cycle test using the differential procedure (LCT) was undertaken on pre-concentrated heavy media sinks and the gold rougher concentrate in Table 1 was cleaned with little upgrade but significant gold losses. In 2020, the new batch flowsheet was built off the 2014 understanding; however, it was undertaken on “fresh feed” and changed to include gravity, which resulted in an understanding that gold, occluded within the mineralization could be concentrated with minimal recovery of lead or zinc, and only minimal recovery of the silver.

It was also observed that by increasing gravity mass pull such as may be seen in a continuous gravity circuit, the gold recovery could be increased to that concentrate. The pyrite flotation was then successfully introduced after the lead, in an effort to remove pyrite earlier in the flowsheet, such that it would cause less interference in the zinc flotation circuit. This resulted in the zinc cleaner 1-3 tails having mainly silver and gold and limited lead and zinc.

Table 1 – Main Zone Flotation Response Comparisons.

Notes:

- Metallurgical recovery varies with grade.

- Numbers may not add due to rounding.

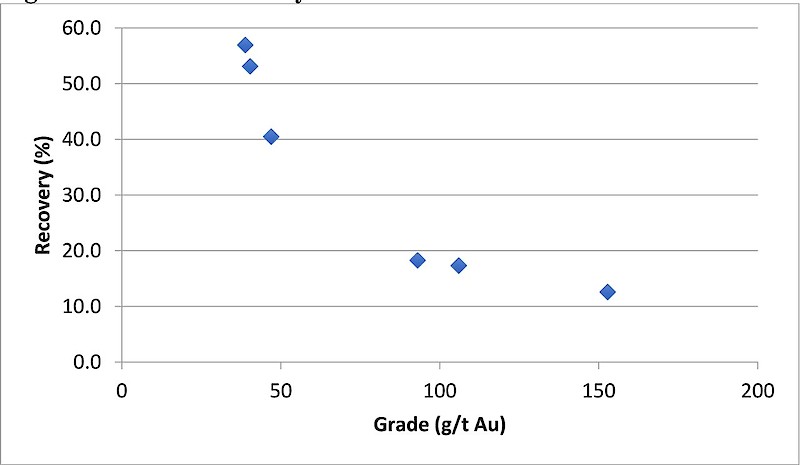

When the gravity products and zinc cleaner tails are combined and further concentrated with gravity, the flowsheet clearly responds such that a grade as high as 153 g/t Au was achieved. This initial upgrade relationship is illustrated in Figure 1.

Figure 1 – Further Gravity Concentration of Combined Gold Concentrate.

Potential Project Improvements from Metallurgical Changes

The potential positive impacts to the process flowsheet are as follows:

- The technology improvements over the last ~20 years with gravity concentrators and fine grinding mills have allowed metallurgical changes to be successfully assessed on the Project’s mineralization.

- Using these technologies in the process flowsheet provides the potential to create gold concentrates of reasonable grade for sale, while at the same time decreasing the amount of mass that is required to be transported. Historically, there have been some metallurgical challenges to achieve this process route, where the mass of concentrate required to ship was more than three times the mass achieved in these recent metallurgical results and the gold grade in that past concentrate lower at approximately 17g/t Au.

- Should alternative hydrometallurgical routes be selected, due to the decreased mass pull, it potentially decreases the size of that circuit.

John Mirko, President & CEO of Rokmaster, stated, “We are very pleased with the results of our metallurgical testing, which have been ongoing for the past several months. The results indicate that conventional flotation and gravity circuits can concentrate the gold at Revel Ridge. The substantial decrease in mass pull of the gold concentrate while maximizing the overall gold recoveries continues to demonstrate the high-quality nature of the Project. Our team believes that these metallurgical results can be improved with some further optimizations and locked-cycle test work producing concentrates for potential sale. These results, together with our increased Mineral Resource Estimate and current drilling program, are solid foundations on which to expand the economic potential of the Main Zone at Revel Ridge. We also continue to make progress on other studies, which could present opportunities to optimize the Project. We have a solid, well-funded work program, in a premier geopolitical jurisdiction, and we are very excited about the next phase of growth for Rokmaster as we work towards developing a potential commercial mine.”

Revel Ridge 2020 Work Program

The Project is now active with underground diamond drilling in progress. The Company’s next objectives are:

- Conduct property-wide exploration and complete an underground diamond drilling program to possibly increase resources at the Main Zone;

- Complete ongoing optimization studies which include metallurgical testing, mine sequencing and capital and mining cost studies to Preliminary Economic Assessment (“PEA”) level and beyond;

- Incorporate results of drilling and optimization studies into further studies to be launched later this year and expected to be completed in the first half of 2021;

- Continue necessary environmental and baseline work for an Environmental Impact Statement; and

- Continue with community engagement for the Project.

Quality Assurance

Base Metallurgical Laboratories Ltd. completed the metallurgical testwork under the supervision of Stacy Freudigmann P. Eng. of Canenco Consulting Corp.

The technical information in this news release has been prepared in accordance with Canadian regulatory requirements as set out in National Instrument 43-101 and reviewed and approved by Stacy Freudigmann,P. Eng., who is independent of Rokmaster.

About Rokmaster

Rokmaster Resources Corp. is an emerging gold-silver and base metal developer with district scale assets in one of the world’s most politically stable mining jurisdictions: British Columbia, Canada.

Rokmaster’s primary assets, all located in British Columbia, consist of: the Revel Ridge polymetallic gold-silver project, currently in the PEA and resource expansion phase; and the Duncan Lake Zinc-Lead Project and the Big Copper Project, which are both exploration projects.

For additional information on the Company and its projects, please visit the Company’s www.rokmaster.com or telephone John Mirko @ (604) 290-4647.

On behalf of the Board of Directors,

“John Mirko”

John Mirko, President and Chief Executive Officer.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

CAUTIONARY NOTE REGARDING FORWARD LOOKING STATEMENTS:

This news release may contain forward-looking information within the meaning of applicable securities laws (“forward-looking statements”). Forward-looking statements are statements that are not historical facts and are generally, but not always, identified by the words “expects,” “plans,” “anticipates,” “believes,” “intends,” “estimates,” ‘projects,” “potential” and similar expressions, or that events or conditions “will,” “would,” “may,” “could” or “should” occur. These forward-looking statements are subject to a variety of risks and uncertainties which could cause actual events or results to differ materially from those reflected in the forward-looking statements, including, without limitation: risks related to fluctuations in metal prices; uncertainties related to raising sufficient financing to fund the planned work in a timely manner and on acceptable terms; changes in planned work resulting from weather, logistical, technical or other factors; the possibility that results of work will not fulfill expectations and realize the perceived potential of the Company’s properties; risk of accidents, equipment breakdowns and labour disputes or other unanticipated difficulties or interruptions; the possibility of cost overruns or unanticipated expenses in the work program; the risk of environmental contamination or damage resulting from Rokmaster’s operations and other risks and uncertainties. Any forward-looking statement speaks only as of the date it is made and, except as may be required by applicable securities laws, the Company disclaims any intent or obligation to update any forward-looking statement, whether as a result of new information, future events or results or otherwise.